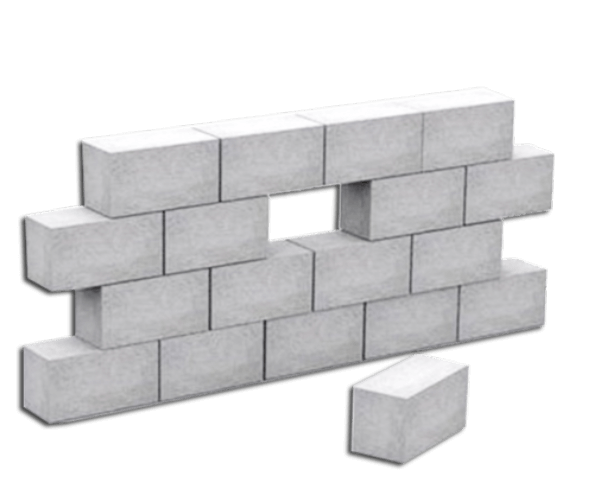

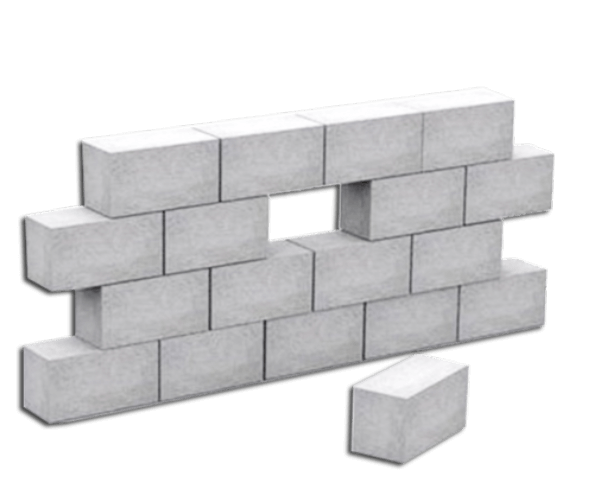

Our Product

A A C blocks are created from a slurry mixture of fly ash, cement, lime, water, and an expansion agent. The slurry is poured and molded into light weight AAC blocks, which are then cured in autoclave equipment. The autoclave's high pressure steam curing mechanism speeds up the curing process of A A C Blocks, resulting in a physically and chemically stable product.